INFORMATION

Product

Overview

BD-FS-81 Optical Fiber Fusion Splicer is small size

optical fiber fusions splicer, mainly used for fusion and protection of common

communications fibers. The rich functionality and ultra-low splice loss make

the splicer adaptive to fiber splicing in various environments. It is featured

with small size, light weight, high reliability, greater environmental

adaptability, dust-resistant, water-resistant and shock-resistant. Multiple

fusion modes and heating modes are available to meet diversified customers’

demands. Fiber loading becomes more convenient and accurate thanks to the

ceramic V-groove of high precision, which is easy for clean and maintenance.

The splicer is capable of dual-directional fusion. The monitor is a touch

screen delivers fresh designed graphical interfaces, which are simple for

operation. The modular pluggable lithium-ion battery of large-capacity ensures

long-time field operations. The auto environment compensation system greatly

improves adaptability of the splicer to hostile environments, so that low-loss

splice can be remained consistent in various environments.

Main

Characteristics

l Small size, light

weight

l 7s fast splicing,

18s highly efficient heating

l 320 times image

magnification, 5mm fusing for ultra-short cleave length

l 300 groups of

splice modes, 100 groups of heating modes, 10000 groups of fusion records /64

images storage

l Ceramic presser

foot, ceramic V-groove, all-in-one fixture

l Dual-directional fusing,

auto fusing, intelligent heat shrink

l USB and SD card

interface, auto update of U disk

l Built-in modular

lithium-ion battery, at least 220 counts of splicing and heating cycles

l GUI (graphical

user interface) and touch screen, convenient for operation

l Dust-resistant,

water-resistant, shock-resistant, greater environment adaptability

Small and light

Small size and

light weight, the splicer is easy to carry and can be lift by one hand.

Water-resistant,

dust-resistant, shock-resistant, greater environment adaptability

Meet IP52

requirements.

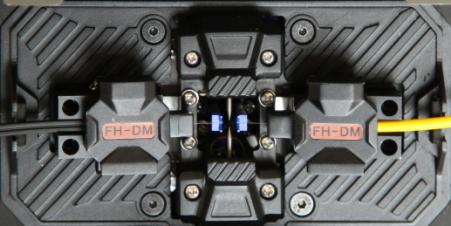

All-in-one fixer

The all-in-one fixture

meet fusion demands of multiple optical fibers, jumpers and rubber-insulted

wires with a cladding diameter of 80~150μm.

All-in-one

optical fiber fixture

Graphical

interfaces and touch screen

BD-FS-81 uses entirely new GUI and touch screen in

design. Operators can set up the splicer and get to know relevant information

of it simply and directly by graphical interfaces.

Entirely new

GUI graphical interfaces and touch screen

Intelligent heat

shrink

A detection unit

is embedded in the heater. The heating function will only be enabled when the

protection sleeve is put in the heater, to avoid mishandling.

Hear and detection unit

Pluggable

lithium-ion battery of large-capacity

The built-in

pluggable lithium-ion battery of large capacity can answer working demand

lasting all day long (typical 220 counts of splicing and heating cycles).

Ceramic V-groove

and ceramic presser foot

Ceramic V-groove

with high precision brings you convenient and accurate placement of optical

fibers and makes cleanup easy.

Carrying case

The carrying case

is novel in design and light in weight, has built-in compact working bench.

Open or close the cover can turn it to a working bench.

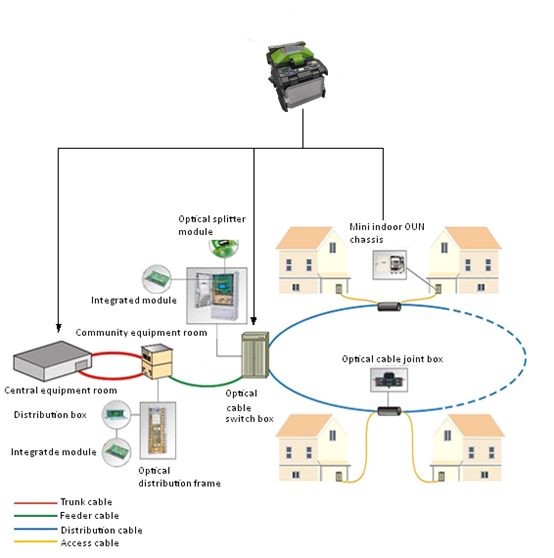

Typical

Applications

BD-FS-81 Optical Fiber

Fusion Splicer is compact equipment deploying the design of ergonomics, which

delivers convenient operation and handy carrying case. Event very short fibers

can be spliced easily. It’s capable of construction and maintenance of optical

fiber line projects (including trunk), emergency repair, production and test of

optical fiber devices and research and study in institutes.

Typical application of BD-FS-81

Optical Fiber Fusion Splicer

Technical

Specifications

|

Model

|

BD-FS-81 Optical Fiber Fusion Splicer

|

|

Motor qty

|

6

|

|

Alignment method

|

Cladding alignment, manual alignment

|

|

Applicable fibers

|

Any common optical fibers, rubber-insulated fibers

and jumpers that meet requirements

of ITU-TG.651~653, ITU-TG.655 and ITU-TG.657.

|

|

Optical

fiber diameter

|

Cladding: 80~150μm, coating layer:

0.1~3mm

|

|

Cleave length

|

5~16mm(coated optical

fiber diameter≤250μm);10mm(coated

optical fiber diameter:0.25~3mm)

|

|

Splice loss(typical)

|

0.02dB(SMF); 0.01dB(MMF); 0.04dB(DSF); 0.04dB(NZDSF)

|

|

Return loss

|

Better than 60dB

|

|

Splicing time (typical)

|

7s (Fast mode)

|

|

Heating time (typical)

|

18s(60mm protection sleeve)

|

|

Tension

|

1.96~2.25N

|

|

Protection sleeve

|

60mm, 40mm and a series of

protection sleeves

|

|

Graphical display

|

High-performance 4.3 inch LCD

|

|

Magnification time

|

320 times/88

times, 700times

|

|

Fusion records

|

10000 groups

|

|

Remote maintenance

|

N/A

|

|

Battery capacity

|

11.1V, 5200mAh

|

|

Battery service life

|

Cycle charging: 300~500

counts, can be replaced by customers

|

|

Electrode service life

|

Typical: 4000 counts, can be replaced by customers

|

|

Construction lighting

|

Built-in lights with high-brightness and wide

lighting area

|

|

Working environment

|

Temp:-10~50℃;Hum: 0~95%RH,height

above sea level: 0~6000m

|

|

Operation interfaces

|

GUI (graphical user interfaces)

|

|

External power

|

AC: 100~240V, 60Hz, 0~1.5A; DC: 10~15V

|

|

Port

|

USB / SD

|

|

Dimensions

|

120mm(W)×130mm(H)×154mm(D)(without rubber anti-vibration pad)

|

|

Weight

|

1.8kg (the battery not included), 2.1kg(included

the battery)

|

Standard Package:

| No. |

Description |

Remarks |

| 1 |

Power cord |

Standard tri-prong cord: 1 pc |

| 2 |

Primary coat stripper |

1 pc |

| 3 |

Jacket remover |

1 pc |

| 4 |

Spare electrode |

1 pair |

| 5 |

Cooling tray |

1 pc |

| 6 |

Cleanup set |

1 set |

| 7 |

User Manual |

1 copy |

| 8 |

carrying case |

1 pc |

Options:

|

No.

|

Description

|

Functionality

|

|

6481B-001

|

U Disk

|

For program update and splice data output

|

|

6481B-002

|

Lithium-ion battery

|

Power supply of the main unit

|

|

6481B-003

|

Power cord of cigarette lighter

|

Connect to on-board battery, for power

supply of the main unit

|

|

6481B-004

|

Fiber

cleaver

|

To cleave fibers

|

Foreign product substitutable:

Sumitomo Fiber fusion splicer TYPE-81C

Related Link:

How many language can Baudcom fiber fusion splicer support?

RFQ:

Question: Can the fiber clamps of the cutter and fusion splicer be disassembled and interchangeable?

Answer: The fiber clamps of the cutter and fusion splicer can be disassembled, but not interchangeable.

Question: Can the fiber clamps of the cutter and fusion splicer be replaced with SOC clamps?

Answer: Yes. It can be replaced with SOC clamps, please confirm the type of SOC clamps before ordering (SOC clamp is an optional accessory and needs to be purchased additionally).

Question: How is the SOC clamp used in the heater of the fusion splicer?

Answer: We will replace the matching heater according to the type of SOC clamp.

Question: There is a SOC clamp that needs to be equipped with a special cutter. If it can cut the normal optical fibers?

Answer: Yes. The special cutter can cut normal optical fibers.

Question: Can the screen of fusion splicer display the types of the fiber while being spliced?

Answer: Yes. The types of the fiber can be displayed on the screen, but not 100% accurate (occurs in all brands of the fusion splicers in the world).

Ordering information

Related Products