INFORMATION

The GCYFY Stranded Loose Tube Air Blown Fiber Optic Cable is a Micro Fiber Optical Cable designed for efficient and reliable long-distance data transmission. The air blown fiber is easy to install and has excellent environmental performance. Stranded air blown fiber optic cable consists of a central loose tube containing multiple strands of optical fiber surrounded by a protective outer sheath. The Stranded Air blown Cable features a miniature design that allows it to be blown to designated locations using air pressure, reducing installation costs.

The Stranded Air blown Fiber Optic Cable is an efficient, convenient and cost-effective cable solution. It uses FRP as reinforcement, is lightweight and has a small diameter.

Cable Features

FRP as strength member.

Polyethylene sheath.

Light weight,small diameter.

Good performance of tensile strength and temperature.

Design Life time over 30 years.

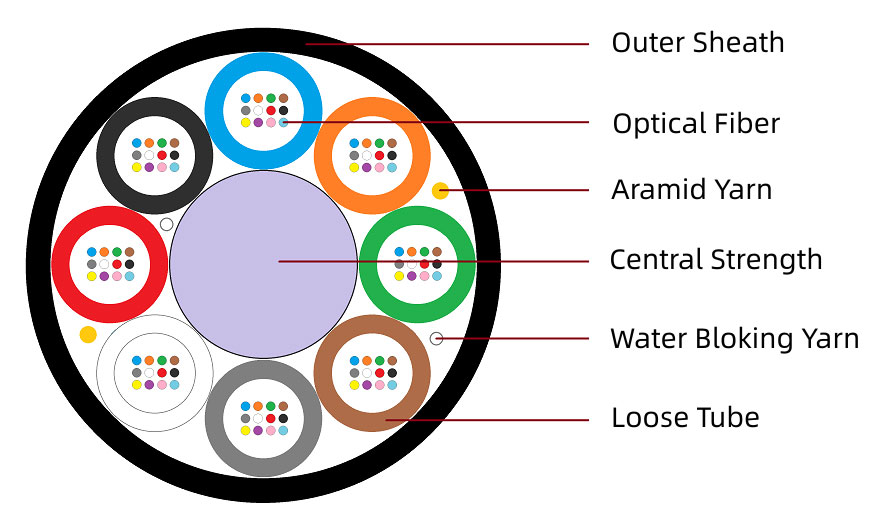

Cross Session of Fiber

Fibre and Loose Tube Identification

The color code of fibre and loose tube will be identification in accordance with the following color sequence, other sequence also is available.

Fibre Color Code

|

1

|

2

|

3

|

4

|

5

|

6

|

Blue

|

Orange

|

Green

|

Brown

|

Grey

|

White

|

7

|

8

|

9

|

10

|

11

|

12

|

Red

|

Black

|

Yellow

|

Violet

|

Pink

|

Aqua

|

Tube Color Code

|

1

|

2

|

3

|

4

|

5

|

6

|

Blue

|

Orange

|

Green

|

Brown

|

Grey

|

White

|

7

|

8

|

9

|

10

|

11

|

12

|

Red

|

Black

|

Yellow

|

Violet

|

Pink

|

Aqua

|

Dimensions and Description

The standard structure of GCYFY air blown fiber optic cable is shown in the following table, other structure and fibre count are also available according to customer requirements.

SN

|

Item

|

Unit

|

Value

|

1

|

No. of fibers

|

count

|

12

|

24

|

48

|

2

|

No. of fibers per tube

|

count

|

12

|

3

|

No. of loose tube&filler

|

count

|

1

|

2

|

4

|

4

|

Loose tube size

|

mm

|

1.5

|

5

|

FRP size

|

mm

|

1.5

|

7

|

Cable diameter

|

mm

|

4.5

|

8

|

Cable weight

|

kg/km

|

17

|

9

|

Outer Sheath

|

material/color

|

PE black

|

10

|

Crush resistance(N/100mm)

|

Long/Short

|

150/500

|

11

|

Tensile strength(N)

|

Long/Short

|

300/1000

|

12

|

Minimum bend radius

|

installation

|

20 x cable diameter

|

installed

|

10 x cable diameter

|

Main Mechanical and Environmental Performance

The main performance of air blown fiber optic cable as below:

Operation temperature:

|

-30℃/+60℃

|

Installation temperature

|

-30℃/+60℃

|

Storage temperature

|

-40℃/+70℃

|

Air Blown Fiber Characteristics

2.1 G.652D

2.1.1 Geometric characteristics

Item

|

Construction

|

Mode field diameter

|

At 1310nm

|

9.2±0.4μm

|

Cladding diameter

|

125±1μm

|

Core concentricity error

|

≤0.6μm

|

Cladding non-circularity

|

≤1.0%

|

Cut-off wavelength (λcc) (for cable)

|

≤1260nm

|

Cut-off wavelength (λc) (for fiber)

|

1180nm~1330nm

|

Primary coating diameter

|

(Not included color layer)

|

245±10μm

|

(Included color layer)

|

250±15μm

|

Coating-cladding concentricity error

|

≤12.5μm

|

Fiber curl radius

|

≥4m

|

2.1.2 Transmission characteristics

Item

|

Performance

|

Attenuation

|

At 1310nm

|

≤0.36dB/km(max.)

|

At 1550nm

|

≤0.21dB/km(max.)

|

Macro bending loss

|

Φ=60mm, 100turns at 1550nm

|

≤0.1dB

|

Chromatic dispersion

|

Within 1288~1339nm

|

≤3.5ps/nm·km

|

At 1550nm

|

≤17ps/nm·km

|

Zero dispersion wavelength

|

1300~1324nm

|

Zero dispersion slope

|

≤0.092ps/nm2·km

|

Dispersion mode bias

|

0.5ps/km1/2

|

Ordering information

Related Products